Blake construction is the bread and butter of the Italian shoe industry. Although Italian shoe manufacturers use a dizzying array of construction techniques, probably more good-quality shoes are made using Blake construction than all of the other methods combined.

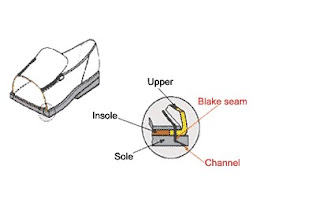

The diagram above shows what is involved with Blake construction, and it should be immediately clear why it is so popular: it’s a lot simpler than Goodyear welting. There is a single row of stitching that attaches the insole to the upper (turned under the insole) and the outsole. Obviously, since the stitching runs inside of the shoe, it’s not possible for a Blake-constructed shoe to be stitched together by hand; so this construction technique is a child of the Industrial Revolution. It’s named for Lyman Reed Blake, and American inventor who patented the machine to accomplish this in 1856. He later sold the patent to a man named Gordon McKay, and one consequently sees this construction method referred to as McKay construction.

Blake construction has two principal advantages. First, because it requires no stitching on the sole edges outside the shoe, it is possible to get extremely close-cut soles with it, much more closely cut than would ever be possible with a Goodyear-welted shoe. Second, because Blake-constructed shoes have fewer layers in the sole, they tend to be more flexible than Goodyear -welted shoes. The principal disadvantages are all outgrowths of the stitching along the insole. This row of stitching can irritate some feet, especially when it is not covered by a sock liner. More seriously, it can wick moisture from the ground into the inside of the shoe. Unless they have rubber soles, Blake-constructed shoes will always be less waterproof than Goodyear-welted shoes, all other things being equal. But there is also a limit to the number of times a Blake-constructed shoe can be re-soled as new holes are being made in the upper leather each time a new sole is attached by the needle. With Goodyear welted shoes the sole stitching goes into the welt which is a seperate piece of leather from the upper leather. So when the welt eventually becomes too riddled with holes a new welt is simply stitched to the upper leather. For these reasons Goodyear welting is the preferred method of construction for the traditional English shoes manufacturers in Northampton; Loake shoes, Sanders shoes and Trickers shoes. Sebago shoes will also use Goodyear welted construction in their more formal shoes. However in their recareational shoes such as the classic Dockside moccasin construction is the preferred method of construction. This technique will be discussed in detail next week. To view a huge range of Goodyear welted shoes vist the Bradshaw and Lloyd website.